Thermal Catalytic ozone destruct units are suitable for all types of Processes specially when Catalytic Poisons are Present or where there are high concentrations of Ozone are Present. Off-gases from a process containing trace levels of un-reacted ozone must be passed through a thermal / catalytic type vent ozone destruct unit prior to its release into the atmosphere for its destruction.

Exhaust gases from processes where ozone has been used invariably contain residual amounts of un-reacted ozone. Before this exhaust can be vented into the atmosphere, it is necessary to decompose the traces of ozone. In most countries it is prohibited to release even low-level concentrations into the atmosphere. There are various methods available to treat vent gas.

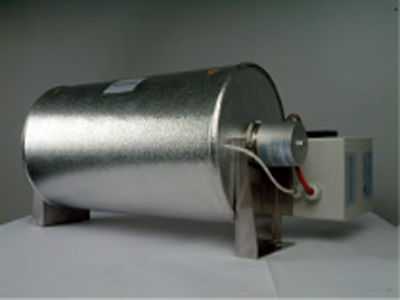

The vent gases leaving the process are routed to the CVODT® vent ozone destruct unit. In the 1st reaction chamber, the gases are heated to around 100°C which radically reduces the half-life of the ozone molecule and, consequently, accelerates the decomposition rate, further after that gas is passed to the 2nd reaction chamber, where in Catalyst is filled, ozone molecule decay's on the surface of the catalyst. Ozone Content in the Gas leaving the Destructor unit is well below the recognized safety limits (< 0.1 PPM). The temperature of 1st reaction chamber is thermostatically controller.

An ozone destructor is a device or system designed to break down ozone molecules (O3) into oxygen (O2) or other harmless substances.

Ozone can be harmful to human health and the environment in high concentrations. Ground-level ozone can cause respiratory problems, eye irritation, and damage to plants and materials.

Ozone destructors are used in various applications where ozone is produced as a byproduct or is present in undesired concentrations. This includes industrial processes, air purification systems, and wastewater treatment plants.

Ozone destructors employ different methods to break down ozone molecules, including thermal destruction (high temperatures), catalytic destruction (using catalysts), chemical destruction (using chemical agents), and UV photolysis (using ultraviolet light).

Ozone destructors help mitigate the harmful effects of ozone by converting it into oxygen or other harmless substances, thereby reducing health risks and environmental damage.

Some ozone destruction methods, such as catalytic destruction and UV photolysis, are more energy-efficient than others, such as thermal destruction. The choice of method depends on factors such as efficiency requirements and energy considerations.

Ozone destructors themselves are generally safe to use when operated correctly. However, proper safety precautions should be followed, especially when dealing with high temperatures, chemical agents, or UV light.

Factors to consider include the concentration of ozone, required efficiency, energy considerations, specific application requirements, and regulatory compliance.

Yes, like any other mechanical or chemical system, ozone destructors may require maintenance to ensure optimal performance and longevity. This may include regular cleaning, replacement of consumable parts, and periodic inspections.

Depending on the application and location, there may be regulations or guidelines governing the use of ozone destructors to ensure environmental protection and public safety. It's important to comply with relevant regulations and standards.